-

Choosing the right tools for CNC milling machine processes.

To ensure CNC milling machines are at their best, manufacturers have to make certain that they pick the best of the tools for completing the job. Cutting tools are different according to the materials and design, so the proper tool must be used to achieve the desired outcome. Face mills, end mills, ball nose end mills and index cutters are just to name a few and can be used for a number of different applications. By using these product, you can achieve a more quality output on your job.

-

Exploring the versatility of CNC milling machines in various industries.

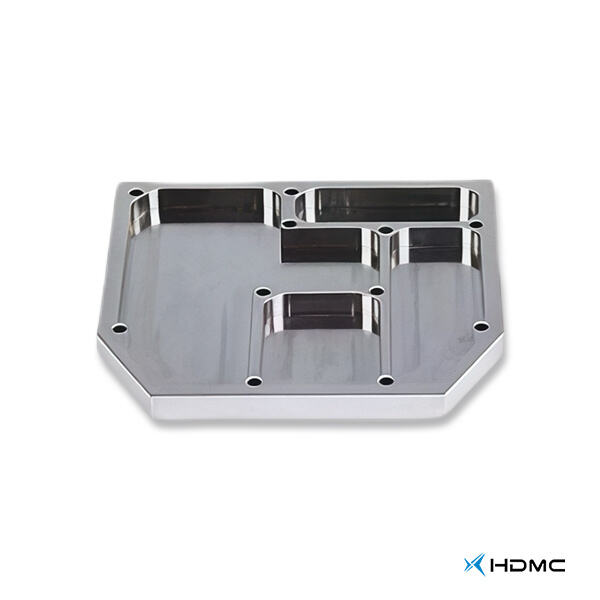

CNC mills are a very versatile machine, which lends itself to a wide variety of industries. Whether it is aerospace, automotive or electronics, Haide Mingcheng CNC machining service are utilized repeatedly, allowing for a variety of products to be manufactured used these manufacturing machines. Their precision means you can make complex and intricate designs providing accurate and specific parts for use in industries that have a need for those exacting specifications.

-

Maximizing productivity with CNC milling machines.

CNC mills allow manufacturers to increase production and streamline operations. These Haide Mingcheng machines can do what they do nonstop for hours on end, stamping out parts rapidly and precisely. What it all boils down to is that manufacturers can make more parts in less time, increasing their throughput and boosting their bottom line. CNC milling machines can also work 24/7, facilitating around-the-clock production and quicker turnarounds on orders. This machine is more time efficient and therefore a great financial asset to businesses in the industry. It is really helpful and used in many applications.