-

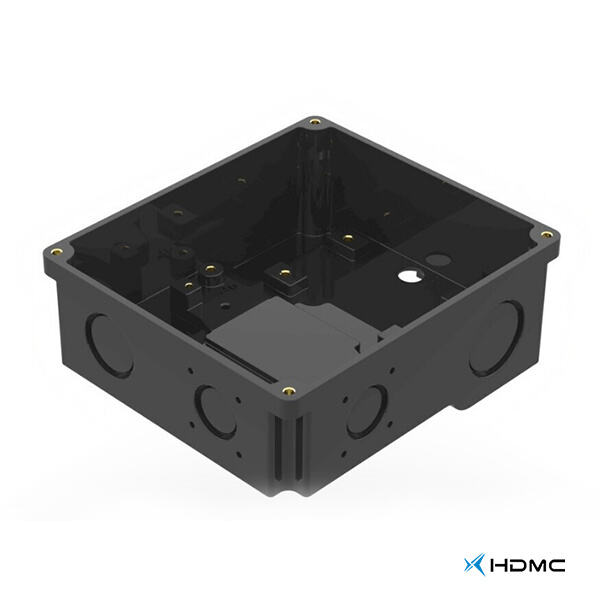

Customize your products with a wide range of materials and colors in injection molding.

At the time of the this model was manufactured, plastic injection blow molding was merely the process of injecting a polymer into a parison to produce a blow molded product.

-

Ensure consistency and repeatability in manufacturing with plastic injection molding.

Consistency is also everything when you want to produce Polishing stuff, and with injection molding, we can guarantee that every item is perfect, each and every time. We use molds to produce the pieces from plastic so we assure every element is an exact size and shape and perfectly high quality. That’s why you can always rely upon every part you get being as good as the last.

-

Explore the benefits of scalability and flexibility in plastic injection molding services.

One of the coolest aspects of injection molding is that it is scalable, adaptable to manufacturing process. That means you can easily create a few parts or a large run based on what the Production orders requires. No matter how many parts you need — whether 1,000 or just five — we adapt our production for your schedule. And if you ever need to change your design, injection molding is flexible enough to let you make updates conveniently and easily.