Applications of CNC in Humanoid Robots

In the humanoid robot manufacturing industry, CNC machining technology demonstrates great potential for the customized production of humanoid robots. Humanoid robots, due to their flexibility and high precision, are increasingly becoming essential tools across various industries. This article will explore the application of customized CNC machining in humanoid robot manufacturing, discussing its processes, technical advantages, and future development directions.

First, customized CNC machining is a key technology for humanoid robot manufacturing. CNC machining with 3- to 5-axis axes enables precise control of mechanical equipment through computer programs, enabling efficient part processing. The process for customized CNC machining of humanoid robot parts primarily involves the following steps:

Design Phase

Before manufacturing a humanoid robot, a detailed design is required. This phase typically involves analyzing the robot's functional requirements, appearance, and kinematic structure. Using CAD software, designers create 3D models of the robot's components. This design determines the complexity and precision requirements of subsequent machining.

Programming and Simulation

After completing the design, engineers need to convert it into the program code required for CNC machining. This process is typically accomplished using computer-aided manufacturing (CAM) software. Engineers use simulation software to simulate the machining process to ensure program accuracy and feasibility, thus avoiding errors during actual machining.

Material Application

After finalizing the design and program, appropriate machining materials are selected based on the structure. Humanoid robot components are typically made of aluminum alloy, plastic, or other lightweight materials to ensure flexibility and stability during movement. The choice of material directly impacts the robot's performance and service life.

Processing Phase

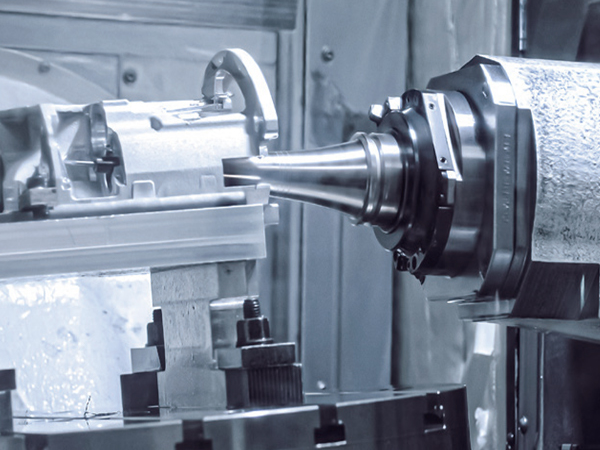

Once the materials are ready, CNC machining begins. Utilizing modern five-axis machining equipment, CNC factories can achieve high-precision machining of complex parts.

Assembly and Debugging

Once part machining is complete, the humanoid robot enters the assembly phase. All parts are assembled according to design requirements to ensure functional consistency and coordination. After assembly, debugging is an essential step, testing the robot's various functions to ensure proper operation.

Quality Control

A strict quality control system is crucial throughout the CNC machining and assembly process. Haide Mingcheng Intelligent Technology adheres to high-quality production standards, ensuring that every component meets design requirements, thereby enhancing the overall quality and reliability of humanoid robots.

Customized CNC machining plays a vital role in the manufacturing of humanoid robots. Precision machining techniques, strict quality control, and a dedicated technical team are essential. With the continuous advancement of technology and the diversification of market demands, the application scope of humanoid robots will further expand, and the prospects for customized CNC machining will also be even brighter.

Hot News

Hot News