Analysis of the Advantages and Application Value of CNC 5-Axis Machining Technology

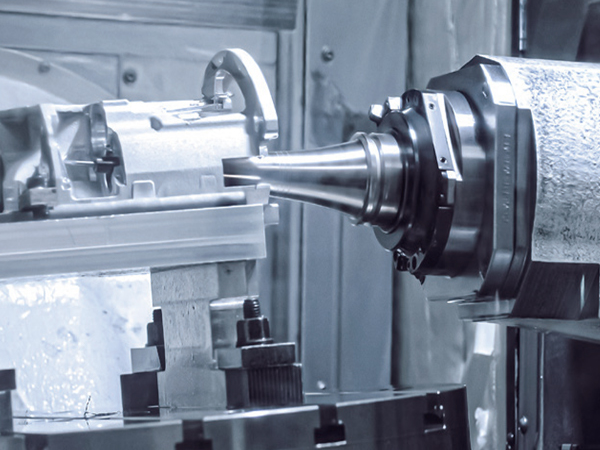

Five-axis machining technology is suitable for machining complex parts, especially those with curved, inclined, or unconventional geometries. Examples include high-precision joint components for humanoid robots; complex curved parts such as automotive engine blocks and cylinder heads; high-precision, high-stability aerospace parts such as turbine blades and inlet guide vanes; and high-end mold components such as die-casting and injection mold cores.

Generally speaking, the accuracy of five-axis machining centers can be divided into four levels: high-precision, precision, standard, and general. High-precision five-axis machining centers can achieve an accuracy of 0.005mm, while standard five-axis machining centers have an accuracy of approximately 0.01mm. It's important to note that machining accuracy is a relative term and should be evaluated based on the actual part and tolerance requirements.

The advantages of five-axis precision CNC part machining lie not only in improved production efficiency but also in its ability to ensure part accuracy and surface quality. By maximizing the flexibility of five-axis machining, the machining process for complex parts can be greatly simplified, reducing cycle time and production costs. In addition, the application of five-axis machining centers represents the direction of advanced technology integration in the machine tool manufacturing industry.

Hot News

Hot News