Paggawa ng produksyon

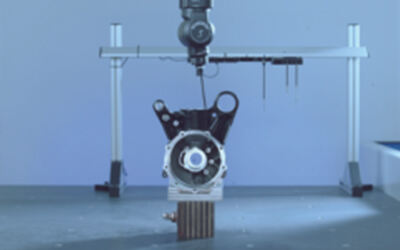

Ang siyentipikong at mahigpit na proseso ng inspeksyon at malalim na kontrol sa kalidad sa sistema ng produksyon ay lumikha ng isang napakadvanced na modelo ng pagmamanufaktura

Ang siyentipikong at mahigpit na proseso ng inspeksyon at malalim na kontrol sa kalidad sa sistema ng produksyon ay lumikha ng isang napakadvanced na modelo ng pagmamanufaktura

Ang Haidi Mingcheng Intelligent Technology (Shenzhen) Co., Ltd. ay isang kumpanya na nag-espesyalisa sa industriya ng pagproseso ng mga precision parts. Ang halos 10 taong karanasan teknikal sa industriya ay nagbigay-daan sa mabilis na pag-unlad ng kumpanya. Hanggang ngayon, ang kumpanya ay mayroong high-end integrated processing equipment, kabilang ang CNC five-axis machines, wire-cutting machines, electrical discharge machines, grinders, lathes, at milling machines, na talagang nakakamit ng isang one-stop service system. Ang saklaw ng serbisyo ng kumpanya ay kinabibilangan ng: mechanical structural components para sa industriya ng robot, mga bahagi para sa kagamitan sa pagtaya ng kalusugan sa industriya ng medikal, vehicle body drive components para sa industriya ng automotive, mga bahagi para sa kagamitan sa automation, battery components para sa industriya ng bagong enerhiya, at auxiliary transmission components para sa industriya ng aerospace.

Upang maprotektahan ang kompanya's mga lihim sa negosyo at sensitibong impormasyon, at matiyak ang kompetisyon ng kompanya at reputasyon, espesyal na inihanda ang sistema ng kompidensyalidad ng kompanya.

Ang kompanya ay may malakas na teknikal na grupo at konpigurasyon ng makina, kayang magbigay ng mabilis na quote para sa produksyon batay sa hinihingi ng customer. Mayroon itong kumpletong sistema ng suplay na sumasaklaw sa mga materyales, proseso, paggamot sa ibabaw, logistika, atbp., na nagpapahintulot dito upang mapabilis ang produksyon at maipadala ang mga produktong may mataas na kalidad.

Kasangkapan ang kompanya ng kumpletong pasilidad sa pagsubok at sistema ng kalidad, kayang mabilis na suriin ang CNC parts at ilabas ang ulat ng pagsubok, natutugunan ang pangangailangan ng mga customer para sa mataas na kalidad.

I-upload ang CAD file. Secure na i-upload ang disenyo ng iyong bahagi sa aming online quote builder

I-configure ang mga espesipikasyon ng iyong bahagi at piliin ang lead time na angkop sa iyong iskedyul. Makakatanggap kaagad ng quote

I-upload ang iyong CAD sa aming online quoting platform

Pipili kami ng pinakamahusay na tagagawa para sa iyong order, at magsisimula kaagad ang produksyon

Tutulan naming buo ang responsibilidad upang tiyakin na ang iyong mga bahagi ay ginawa ayon sa aming mga pamantayan

Aayusin namin ang pagpapadala ayon sa mga kinakailangan sa pag-pack na ibinigay

May karagdagang tanong tungkol sa mga order ng serbisyo sa produksyon ng CNC manufacturing?

Sa mataas na kalidad ng paghahatid, ang pagtiyak sa kalidad ng proyekto ay hindi lamang isang teknikal na isyu, kundi kasali ang bawat link mula sa pagtukoy ng mga kinakailangan hanggang sa paghahatid ng proyekto. Ang susi sa pagtiyak ng mataas na kalidad ng aming mga proyekto ay nakamit sa pamamagitan ng pinong proseso ng pamamahala, malinaw na pagtatakda ng mga layunin, sapat na komunikasyon at koordinasyon, at matibay na pamamahala ng panganib.

1. Tiyaking malinaw at komprehensibo ang mga kinakailangan ng proyekto;

2. Mayroon kaming sistematikong mekanismo ng kontrol sa kalidad at regular na inspeksyon sa kalidad sa panahon ng pagpapatupad ng proyekto;

3. Kailangan naming unti-unting mapabuti ang mataas na kalidad ng paghahatid ng proyekto sa pamamagitan ng pagbubuod ng karanasan at patuloy na pagpapabuti ng mga paraan ng pamamahala ng kalidad;

Sa buong proseso ng kontrol sa kalidad, kami ay nagsasagawa ng regular na pagsusuri sa kalidad, nagpapatupad ng pagsasanay sa kalidad, at gumagamit ng siyentipikong mga tool sa pagtatasa ng kalidad upang matiyak ang mahusay na paghahatid ng mga proyekto.

Ang mga bahagi ng CNC machining ay walang minimum na dami ng order o MOQ, ibig sabihin, maaari naming mahusay na ma-produce ang mga prototype na bahagi at kahit mga pasadyong bahagi na isang beses lamang gamitin nang may kaunting gastos, na hindi posible sa ibang paraan ng pagmamanupaktura. Halimbawa: Para sa mga plastik na bahagi, kinakailangan munang gumawa ng isang metal na mold, na isang mahal na proseso; dahil dito, hindi tayo makatipid sa paggawa ng ilang mga pasadyong bahagi. Dahil walang MOQ sa mga bahaging machined, ang teknolohiya ng CNC machining ay angkop para sa mga pabrika at negosyo na may iba't ibang pangangailangan sa dami, disenyo na pasadyo, at prototype.

Makipag-ugnayan sa aming koponan ng suporta sa customer upang talakayin ang anumang bagay tungkol sa produksyon ng mga bahaging may kalidad sa pagmamanupaktura.