맞춤 주사 성형 서비스

우리의 전문 주사 성형 서비스 회사 네트워크에서 다양한 맞춤 서비스를 이용하세요. 프로토타입 및 생산 도구 제작 가능. 무료 견적과 전문가 피드백을 받으려면 부품을 업로드하세요.

우리의 전문 주사 성형 서비스 회사 네트워크에서 다양한 맞춤 서비스를 이용하세요. 프로토타입 및 생산 도구 제작 가능. 무료 견적과 전문가 피드백을 받으려면 부품을 업로드하세요.

3mm(0.12인치)에서 2m(79인치)까지 다양한 복잡도의 부품을 제작합니다. 납기 시간은 최소 12일이며, 글로벌 생산 옵션을 제공합니다. 부품 크기, 복잡성, 양에 따라 제조 파트너들은 일반적으로 20톤에서 3,000톤 주사 성형기를 사용하며, 요청 시 DIN 16901-130 및 더 높은 정밀도를 제공할 수 있습니다.

회사는 2대의 Shadick 기계, 4대의 베이징 Jingdiao 기계, 4대의 Taihai Xiehong 기계, 2대의 FANUC 고속 CNC 가공 센터, 3대의 전기 방전 가공기(EDM), 4대의 정밀 미러 EDM 기계, 2대의 천천히 이동하는 선 자르기 기계, 4대의 디지털 표시 대형 밀링 머신, 5대의 표면 정밀 연마 기계와 여러 다른 금형 제작 장비, 12대의 Haitian 주사成型 기계, 그리고 2개의 스크린 인쇄 생산 라인을 보유하고 있습니다. 또한 하나의 조립 라인이 있습니다. 동시에 금형의 정밀도 요구 사항을 충족하기 위해 회사는 국제적으로 선진적인 투영기와 3차원 측정 장비도 갖추고 있습니다.

주사 성형 부품은 다양한 색상으로 맞춤 설계할 수 있습니다

고객 요구 사항에 따라. 고객은 국제 Pantone 컬러 카드를 기반으로 원하는 색상을 선택할 수 있습니다.

맞춤화를 위해.

색상이 풍부하고 배송 속도가 빠릅니다.

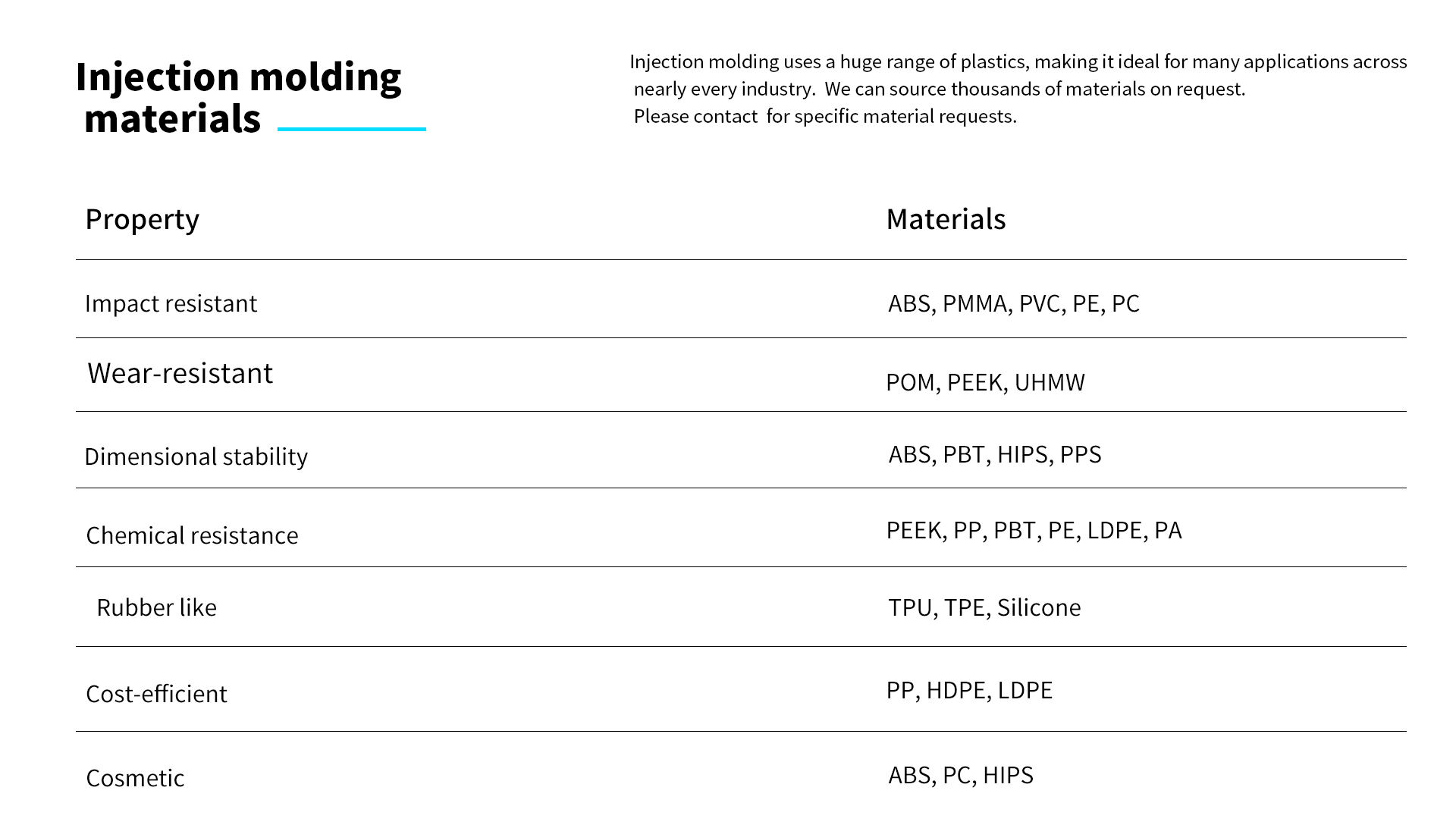

주사 성형은 거의 모든 산업에서 다양한 응용 분야에 적합한 다수의 플라스틱을 사용합니다. 우리는 요청에 따라 수천 가지 소재를 확보할 수 있습니다.

| 재산 | 재료 |

| 충격에 강함 | ABS, PMMA, PVC, PE, PC |

| 내마모성 | POM, PEEK, UHMW |

| 차원적 안정성 | ABS, PBT, HIPS, PPS |

| 화학물질 저항성 | PEEK, PP, PBT, PE, LDPE, PA |

| 고무 같은 | TPU, TPE, 실리콘 |

| 비용 효율성 | PP, HDPE, LDPE |

| 화장품 | ABS, PC, HIPS |

주사 성형에 자주 사용되는 열가소성 재료는 다음과 같습니다:

● 아크릴 (PMMA)

● 아크릴니트릴 부타디엔 스티렌 (ABS)

● 나이론 폴리아미드 (PA)

● 폴리카보네이트 (PC)

● 폴리에틸렌 (PE)

● 폴리포름알데히드 (POM)

● 폴리프로필렌 (PP)

● 폴리스티렌 (PS)

● 열가소성 엘라스토머 (TPE)

● 열가소성 폴리우레탄 (TPU)