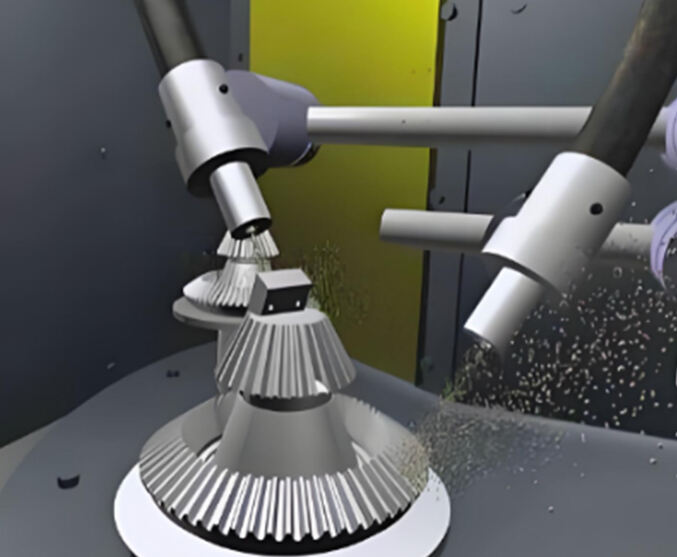

Eksempel på en del behandlet med perlestål

-

Før perlestålbehandling

-

Efter perlestålbehandling

Perlestålbehandling renser og jævner overfladen af dine tilpassede komponenter, hvilket forbedrer funktionaliteten og den kosmetiske kvalitet. Det efterlader en ensartet mat eller satineret tekstur på de maskinerede dele ved anvendelse af glasperler under højt tryk på komponenterne. En udelukkende kosmetisk behandling er tilgængelig på forespørgsel.

| Anvendte materialer | Medier | Kosmetisk tilgængelighed | Visuelt udseende |

| Aluminium, Kobber, Blød stål, Titan, Møntmetal, Legeret stål, Rustfrit stål, Værktøjsstål | Glasperler med korn #120 | Cosmetisk efter anmodning | Korrelagt, let mat tekstur. Skærebænke er reduceret for "non-cosmetic"-valg og helt fjernet på primære flader for "cosmetic"-valg. |

Overfladebehandling er en procesmetode, der kunstigt danner et overfladelag på substratmaterialets overflade med mekaniske, fysiske og kemiske egenskaber, som adskiller sig fra selve substratet. Formålet med overfladebehandling er at opfylde krav til korrosionsbestandighed, slidstyrke, dekor eller andre særlige funktioner for produktet. For metalstøbning er de overfladebehandlingsmetoder, vi almindeligvis anvender, mekanisk slibning, kemisk behandling, overfladeforbedring og overfladesprøjtningsprocesser. Overfladebehandling omfatter rengøring, fejning, afslibning af burrs, fjernelse af oliepletter og fjernelse af oxidhinde fra arbejdsemnets overflade.

Stribning er en blæste-proces, der anvender højtryks fine glaskugler til at rense eller afslutte overflader. Producenter anvender som udgangspunkt denne teknologi på metaller, plastik, glas og gummi for at skabe en fremragende overfladebehandling. Blæstning er en multifunktions-overfladebehandlingsproces, som kan spille flere roller under produktionsprocessen, herunder fjernelse af belægninger eller korrosion, forberedelse af overfladen til belægninger, eliminering af visuelle fejl, ændring af overfladens finish og fjernelse af overflade-ridser. Sandblasting-processen bruger komprimeret luft til at sprøjte sandpartikler på arbejdsemnets overflade, hvilket skaber et højhastigheds-impact og fjerner overfladeforureninger og forbedrer overfladekvaliteten. Den anvendes bredt inden for industrier såsom bilproduktion, luftfart, maskinproduktion og elektronisk udstyr.

Stribning er en proces, hvor tørre stribningsmidler kan være stålsand, aluminiumoxid, kvartsand, siliciumcarbid osv., men det mest anvendte materiale er kvartsand. Ud fra delenes materiale, overfladetilstand og behov for behandling kan stribningsmidler af forskellige materialer vælges.

Som en let færdigbehandlingsmetode giver strålebehandling fremragende resultater, især for dele med komplekse former, såsom impeller motorblade, forskellige forme (pengeforme, røgelsesmønter, mindemønter), hvilket ikke kan sammenlignes med nogen anden metode. Strålebehandling er den mest økonomiske metode til polering af keramik, diamanter samt guld- og sølvsmykker.